When you are searching for issues about quality control, you may feel confused. Because sometimes you can see “quality assurance”. “quality control” and “quality assurance” sometimes are used in a mix. But actually, they are different and they shouldn’t be used with the same meaning.

What is Quality Assurance (QA)?

Quality assurance is to plan production activities & requirements and ensure these requirements will be fulfilled in the whole developing and manufacturing process.

Take a new high-end watch production for example.

QA has to do watch research, evaluate watch design, analyze watch sales and business, contact client’s specific requirements, etc. During these processes, QA can foresee the potential problems which haven’t yet happened to the watches. Then QA will pre-define the production processes and standards to prevent these problems. What is Quality Control (QC)?

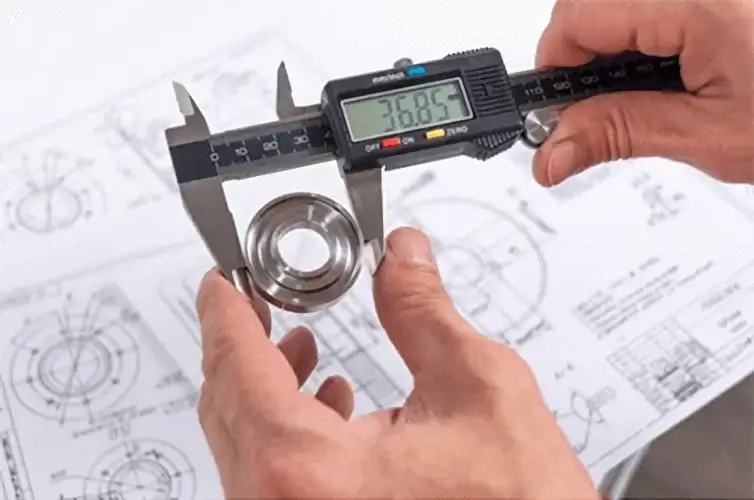

Quality control is a practical activity to inspect and test the products and the production process to ensure the finished products meet quality standards.

Still take the new high-end watch production for example.

QC inspect watches have been produced. QC finds and rejects defective products, like watches with scratches or painted the wrong color. These defective watches will be asked to rework to ensure the goods shipped to you meet your requirements.

Quality Assurance (QA) V.S. Quality Control (QC)

To have a better distinction between QA and QC, their differences can be roughly divided into the following points.

1. Different Focus

QA aims to prevent any quality problems before they occur on products. It is proactive.

QC aims to find & reject defective products when problems have happened. It is reactive.

2. Different Orientation

QA arranges production activities and standards in advance and ensures they are followed in the whole development life cycle of the project. Thus, it is a line function. It is process-oriented and relatively long-term.

QC inspects products when or after they are manufactured. It only involves the test phase of the life cycle. Thus, it is a staff function. It is result-oriented and relatively short-term.

3. Different Function

QA can be seen as a managerial tool. It can control and guide the whole development life cycle to assure product quality.

QC can be seen as verifying tool, finding and correcting defects before entering the market.

4. Different Responsibility

QA involves communicating with various people and departments to assure quality. So it requires a larger team to deal with different work.

QC mostly involves product inspection and testing in the factory to measure the quality. So it requires a smaller team specializing in product inspection/testing.

If QA is Done, is QC Still Needed?

If you want to develop a completely new product, and your team has made the production plans and established standards in “QA”, how can you ensure all these pre-defined things can be followed correctly and completely throughout the life cycle of the project?

The answer is that QC is usually conducted after QA is done. QA is more like making laws and regulations to prevent people from crimes. While QC is like a policeman to catch criminals when the laws and regulations are violated.

If the pre-defined processes and standards are not followed, there will be some problems with the products. Then QC measures the products to find and correct the defects. Therefore, QC is still needed after QA to ensure product quality.

What’s more, not all sourcing projects require QA, but nearly all need QC. If you purchase some common goods, like cups and bottles, or if you just do some simple customization like logo, having QC inspect the goods in different sourcing phases is enough.